Bandsaw Machines

Bandsaw Machine in Coimbatore

November 30, 2023

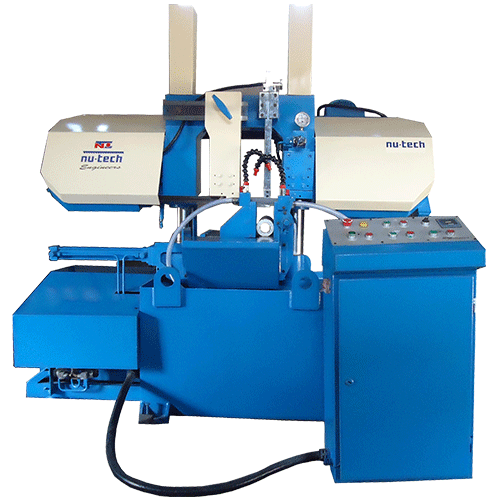

Bandsaw Machine Manufacturer

December 5, 2023Bandsaw Machines: Essential Tools for Precision Cutting

In the realm of cutting and shaping materials, bandsaw machines stand out as indispensable tools, offering precision, versatility, and efficiency.

Understanding Bandsaw Machines: A Cut Above the Rest

Bandsaw machines are specialized tools used for cutting various materials, including wood, metal, and plastic. They consist of a long, sharp blade stretched between two or more wheels, creating a continuous band. This unique design allows for uniform cutting action and the ability to cut irregular or curved shapes, making bandsaw machines a go-to choice in many workshops and industries.

Types of Bandsaw Machines: Meeting Every Cutting Need

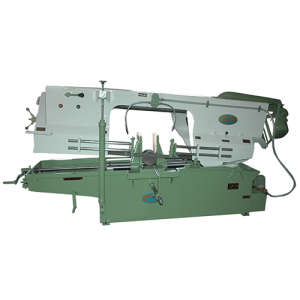

Manual Bandsaw Machine

|

|

|

|

|

|

|

- Ideal for Beginners: These machines require manual control, making them suitable for hobbyists and small workshops.

- Customizable Cuts: Operators can adjust the blade manually for unique cuts, offering creative freedom.

- Cost-Effective: Generally less expensive, they are a great starting point for those on a budget.

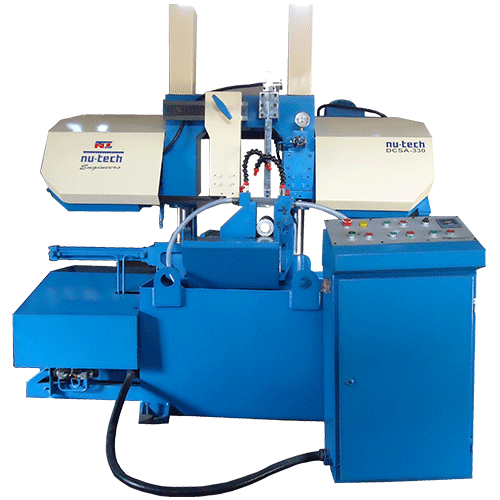

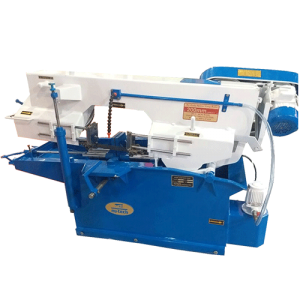

Semi-Automatic Bandsaw Machine

|

|

|

- Enhanced Productivity: Semi-automatic machines blend manual and automated features, increasing cutting speed and consistency.

- User-Friendly: They reduce the operator’s workload while maintaining control over the cutting process.

- Versatile Applications: Ideal for medium-sized workshops and varied cutting tasks.

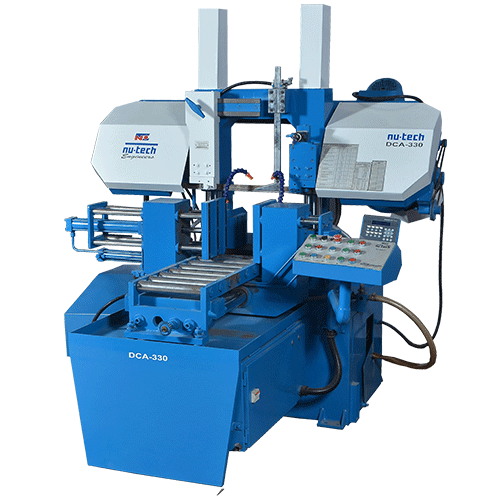

Automatic Bandsaw Machine

|

|

|

- High Efficiency: Fully automated, these machines are designed for high-volume, repetitive tasks.

- Precision and Consistency: They ensure uniform cuts, crucial in large-scale production.

- Time-Saving: With programmable settings, automatic machines save significant time and labour.

Features and Benefits:

- Precision Cutting: Bandsaw machines offer unmatched accuracy, essential for intricate designs and detailed work.

- Versatility: Capable of cutting a variety of materials, these machines adapt to different project needs.

- Efficiency: With faster cutting times and less waste, bandsaw machines boost productivity.

- Safety: Compared to other cutting tools, bandsaw machines are generally safer, thanks to their design and features.

Applications and Usages:

Bandsaw machines find their place in numerous settings. In woodworking, they are essential for intricate cuts and curves. Metalworking industries rely on them for precise, clean cuts in metal fabrication. Even in the field of material science and education, these machines are used for sample preparation and demonstration purposes.

Choosing the Right Bandsaw Machine

Selecting the right bandsaw machine depends on your specific needs. For hobbyists or small projects, a manual bandsaw machine might suffice. Semi-automatic machines offer a balance for those needing more speed and efficiency without the high cost of full automation. For industrial-scale production, an automatic bandsaw machine is indispensable.

Conclusion: The Cutting Edge of Your Workshop

In conclusion, bandsaw machines are crucial in various industries for their precision, versatility, and efficiency. Understanding the different types, their features, and their benefits helps you make an informed decision for your specific needs, ensuring your workshop or industrial operation stays at the cutting edge of productivity and quality.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242