Benefits of Bandsaw Machines

Bandsaw Machine in Coimbatore

April 4, 2024

Applications of Bandsaw Machines

April 9, 2024In the realm of metalworking and woodworking, precision and efficiency are paramount. That’s where bandsaw machines come into play, revolutionizing how materials are cut with their versatility and accuracy. As a leading manufacturer, NU-TECH Engineers stands at the forefront of this innovation, offering a range of bandsaw machines tailored to meet diverse industrial needs. Here, we delve into the benefits of incorporating a bandsaw machine into your operations, highlighting how NU-TECH’s solutions can elevate your projects.

Unmatched Versatility

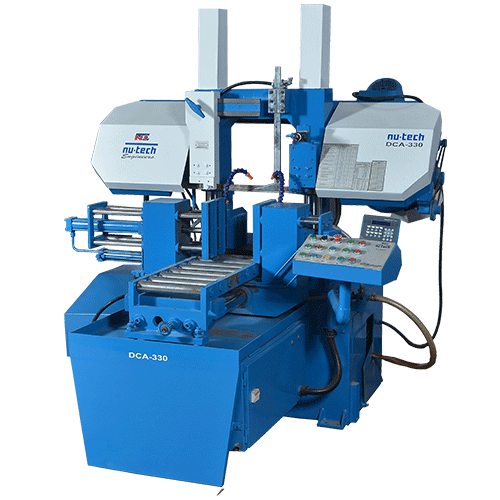

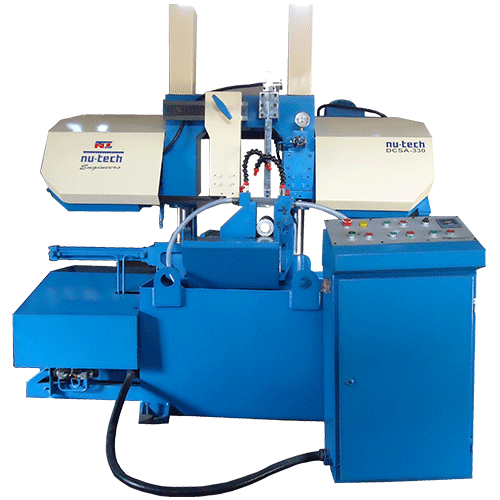

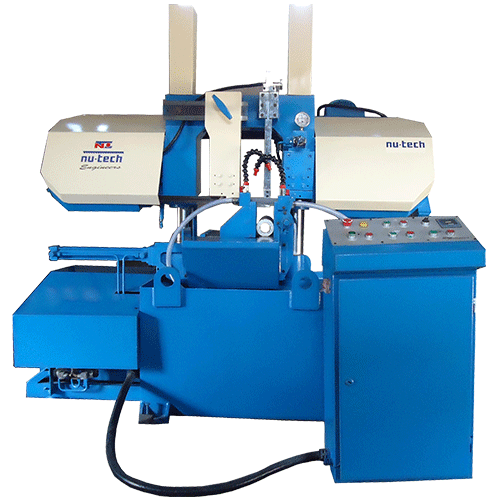

Bandsaw machines are celebrated for their unparalleled versatility. Capable of making straight cuts, curves, or complex shapes, these machines are indispensable tools in any workshop. NU-TECH Engineers offers Manual, Semi-Automatic, and Automatic Bandsaw Machines, each designed to cater to different levels of operational complexity and precision needs. Whether you’re working on intricate designs or straightforward cuts, there’s a bandsaw that fits your requirements.

Superior Precision and Accuracy

Precision is a non-negotiable in the cutting process. NU-TECH’s bandsaw machines are engineered to ensure every cut is executed with the highest degree of accuracy. This precision minimizes material wastage and enhances the quality of the finished product, making it an essential tool for businesses aiming to maintain a competitive edge through superior craftsmanship.

Efficiency and Productivity

Efficiency in cutting processes directly impacts overall productivity. Bandsaw machines from NU-TECH are designed to optimize cutting speeds while ensuring minimal downtime, thus significantly enhancing operational efficiency. The choice between Manual, Semi-Automatic, and Automatic models allows businesses to select the machine that best aligns with their production volume and speed requirements, ensuring a boost in productivity.

Cost-Effectiveness

Investing in a bandsaw machine is a cost-effective decision for several reasons. Firstly, precision cutting reduces material wastage, leading to significant savings in raw materials over time. Secondly, the durability and low maintenance requirements of NU-TECH’s bandsaw machines ensure a long service life, providing an excellent return on investment.

Enhanced Safety Features

Safety is a critical consideration in any workshop setting. NU-TECH Bandsaw Machines come equipped with advanced safety features designed to protect operators from potential hazards. These features include blade guards, emergency stops, and lockout switches, among others, ensuring a safe working environment.

Customizable Solutions

Understanding that every workshop has unique needs, NU-TECH offers customizable bandsaw solutions. Whether it’s adjusting the blade speed, incorporating specific cutting capacities, or adding unique safety features, NU-TECH works closely with clients to tailor machines to their specific requirements.

After-Sales Support and Services

NU-TECH’s commitment to customer satisfaction extends beyond the sale of bandsaw machines. With comprehensive after-sales support and services, customers can rely on prompt assistance for maintenance, repairs, and parts replacement, ensuring minimal downtime and sustained operational efficiency.

Conclusion

The integration of a bandsaw machine into your workshop can significantly enhance cutting precision, efficiency, and safety, while also being a cost-effective investment in the long run. With NU-TECH Engineers’ range of Manual, Semi-Automatic, and Automatic Bandsaw Machines, businesses can find the perfect match to meet their operational needs and elevate their metalworking projects to new heights of excellence.

NU-TECH Engineers is not just a manufacturer; it’s a partner in your journey towards achieving operational excellence through innovative cutting solutions. Explore our range of bandsaw machines and experience the difference in precision, efficiency, and reliability.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242