Applications of Bandsaw Machines

Benefits of Bandsaw Machines

April 6, 2024

Bandsaw Machines in India

April 11, 2024Bandsaw machines, versatile tools in the world of manufacturing and woodworking, stand out for their efficiency and precision. These machines, equipped with a long, sharp blade consisting of a continuous band of toothed metal stretched between wheels, excel in cutting a variety of materials, from wood to metal. NU-TECH Engineers, a premier manufacturer of bandsaw machines, offers a range of models designed to meet diverse cutting needs.

Manual Bandsaw Machine

Manual bandsaw machines, the simplest form of bandsaw equipment, require the operator’s guidance to control the cut. Ideal for small workshops or hobbyist spaces, these machines are perfect for custom and precision cuts in materials like wood, metal, or plastic. Their applications extend from crafting intricate pieces of furniture to detailed sculpting and model making, providing artisans and DIY enthusiasts the tools needed to realize their creative visions.

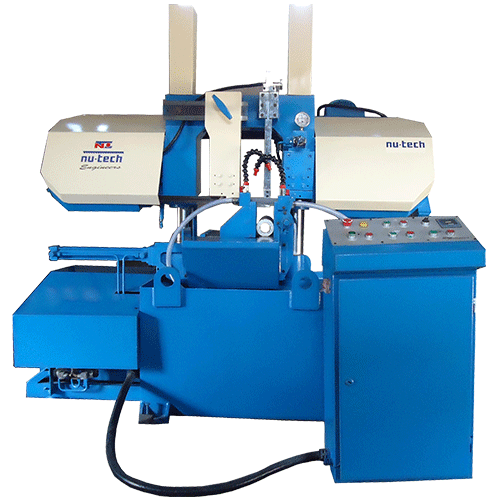

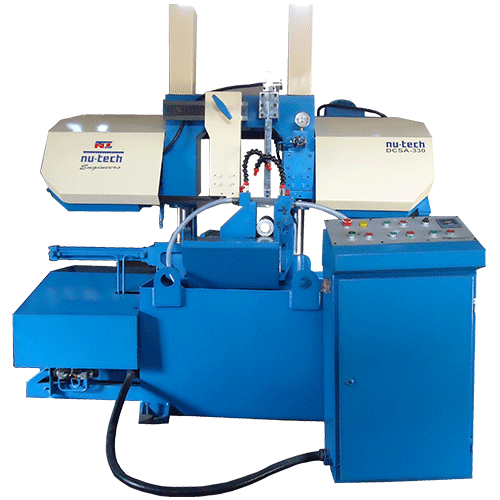

Semi-Automatic Bandsaw Machine

Semi-automatic bandsaw machines offer a balance between manual control and automated features. These machines are equipped with features that automate part of the cutting process, such as clamping and blade descent, while the operator still plays a role in the setup and oversight of the operation. They are particularly suited for small to medium-scale production environments where repetitive cuts are common, but where some level of manual adjustment is desired for flexibility. Industries like automotive, construction, and small-scale metal fabrication find semi-automatic bandsaw machines invaluable for their ability to efficiently cut through metal pipes, beams, and complex profiles.

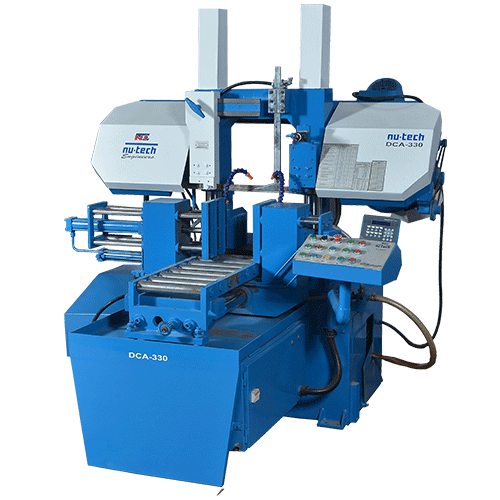

Automatic Bandsaw Machine

Automatic bandsaw machines represent the pinnacle of efficiency and precision in material-cutting technology. Fully automated operations allow these machines to perform cuts with minimal human intervention, making them ideal for high-volume production environments. Automatic bandsaws with advanced features cut production times and labour costs significantly. Their applications span across various industries, including aerospace, shipbuilding, and large-scale metal fabrication, where precision and efficiency are paramount. These machines effortlessly handle bulk cutting operations, cutting everything from steel bars to complex alloy materials with precision.

The Role of Bandsaw Machines in Industry

A Bandsaw machine plays a crucial role in various industrial applications. Versatile for simple to complex cuts, bandsaws are crucial in manufacturing, woodworking, plastics, and food processing. NU-TECH Engineers’ commitment to quality and innovation is evident in their range of bandsaw machines. Whether it’s the precision required in a manual operation, the balance of automation in semi-automatic machines, or the efficiency of fully automatic systems, NU-TECH Engineers provides solutions that cater to the diverse needs of industries worldwide.

Conclusion

The applications of bandsaw machines are as diverse as the models available. From manual to automatic, each type of bandsaw machine offers unique advantages tailored to specific industrial needs. NU-TECH Engineers stands at the forefront of this technology, providing high-quality bandsaw machines that promise precision, efficiency, and reliability. As industries continue to evolve, the versatility of bandsaw machines will remain indispensable, making them a crucial tool in the manufacturing landscape.

On the other hand, any request in regards to our thing range and our associations make it a feature us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242