Bandsaw Machines

Bandsaw Machine in Coimbatore

May 2, 2024

Bandsaw Machine Manufacturer

May 7, 2024Unlock Precision with NU-TECH Engineers’ Bandsaw Machines

At NU-TECH Engineers, we understand the critical role precision plays in metalworking and woodworking. Our range of bandsaw machines is designed to meet diverse cutting needs, from small workshops to large industrial environments. Whether you’re cutting metals or wood, NU-TECH has the perfect solution for you.

Types of Bandsaw Machines at NU-TECH Engineers

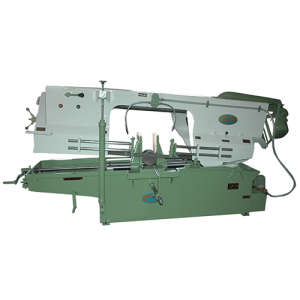

Manual Bandsaw Machine

Ideal for businesses that require hands-on control. Our manual bandsaws provide flexibility and precision with every cut, making them perfect for custom projects.

|

|

|

|

|

|

|

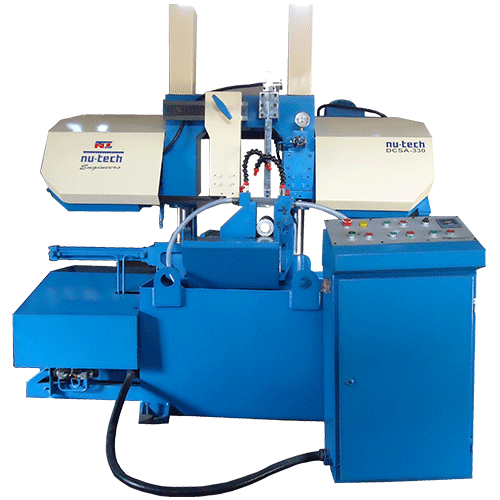

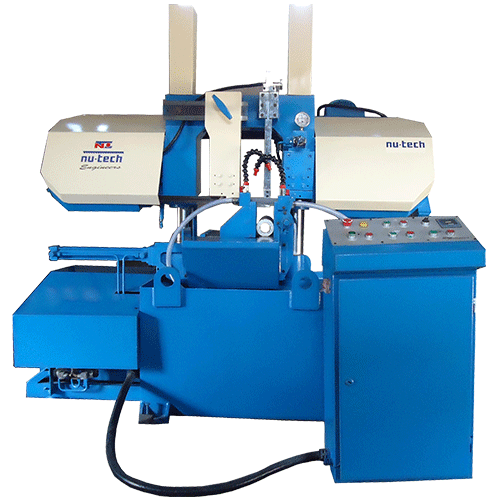

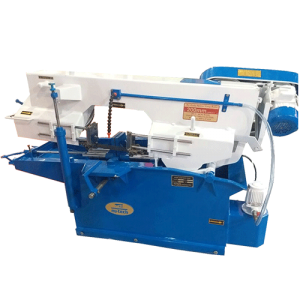

Semi-Automatic Bandsaw Machine

A step up in efficiency, our semi-automatic models combine user control with automated features. They reduce labour intensity while maintaining high-quality cuts.

|

|

|

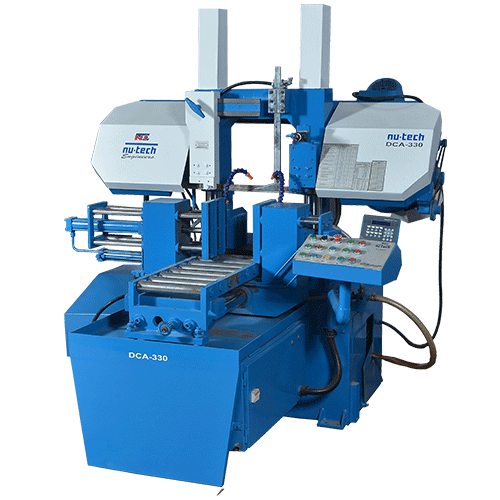

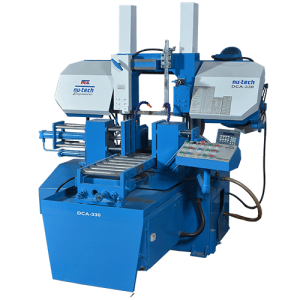

Automatic Bandsaw Machine

For high-volume, repetitive tasks, nothing beats our automatic bandsaw machines. They offer fast, consistent cuts with minimal operator involvement, maximizing your production output.

|

|

|

Why Choose NU-TECH Bandsaw Machines?

- Durability: Built to last, our bandsaw machines withstand rigorous use in demanding environments. The robust construction ensures longevity and consistent performance.

- Precision Cutting: With advanced technology, our machines deliver precise cuts. This precision helps in minimizing material waste and improving the quality of the finished product.

- Safety Features: User safety is paramount at NU-TECH. Our bandsaw machines come equipped with essential safety features to protect operators from potential hazards.

- Ease of Use: Designed with the user in mind, our bandsaws are easy to operate. Even those new to bandsaw machines can achieve professional-grade cuts with minimal training.

- Customer Support: NU-TECH prides itself on exceptional customer service. From installation to maintenance, our team is here to support you every step of the way.

Applications :

Our bandsaw machines are versatile and can be used in various applications:

- Metal Fabrication: From intricate jewellery pieces to robust machine parts, our bandsaws handle it all.

- Woodworking: They are ideal for furniture making, crafting detailed wooden objects, and more.

- Construction: Our machines assist in cutting materials used in construction, ensuring that everything fits perfectly.

Maintenance Tips for Optimal Performance

To keep your NU-TECH bandsaw machine in top condition:

- Regularly clean the machine to prevent material build-up.

- Lubricate moving parts to reduce wear and tear.

- Check the blade for sharpness and replace it if necessary.

- Ensure that all safety guards are in place before operation.

Ready to Enhance Your Cutting Operations?

Explore our website or contact us directly to find out more about our bandsaw machines. Whether you’re interested in a manual, semi-automatic, or automatic model, NU-TECH Engineers has the right tool to help you achieve precise, efficient cuts.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242