Bandsaw Machines Manufacturer

Bandsaw Cutting Machines Manufacturer

June 15, 2024

Bandsaw Metal Cutting Machine Manufacturer

June 20, 2024Bandsaw Machines Manufacturer

When it comes to cutting materials precisely and efficiently, bandsaw machines are indispensable in the manufacturing industry. NU-TECH Engineers stands out as a leading Bandsaw Machines Manufacturer, offering models that cater to various needs. Whether you’re a small workshop or a large industrial operation, understanding the right bandsaw machine to use can significantly boost your productivity.

Manual Bandsaw Machines: The Basics

Starting with the simplest form, NU-TECH’s manual bandsaw machines are designed for straightforward operations. Ideal for workshops where intricate cuts are less frequent, these machines allow direct control over the cutting process. They require an operator to manually feed and adjust the material, making them suitable for custom jobs or smaller batches. The precision and simplicity of manual bandsaws make them a valuable asset for any fabricator.

|

|

|

|

|

|

|

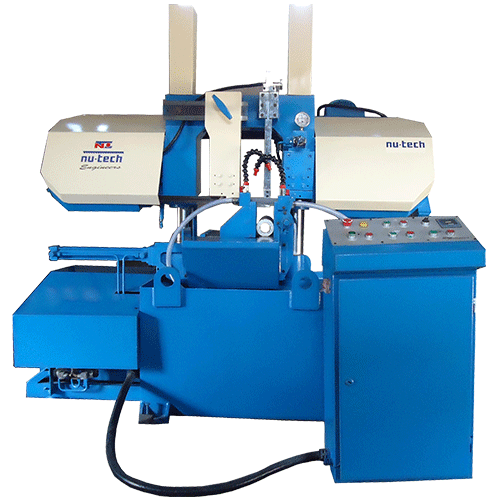

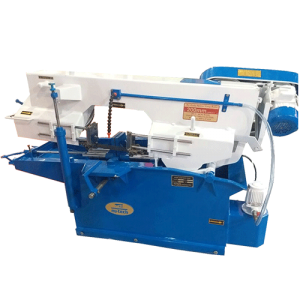

Semi-Automatic Bandsaw Machines: Enhanced Efficiency

For operations that bridge the gap between manual labour and full automation, semi-automatic bandsaw machines are the perfect fit. These units streamline the cutting process by automating certain functions, such as clamping and blade descent. This allows the operator to handle other tasks while the machine runs, improving workflow and reducing labour costs. NU-TECH’s semi-automatic models are popular among medium-sized enterprises that aim to increase output without compromising on quality.

|

|

|

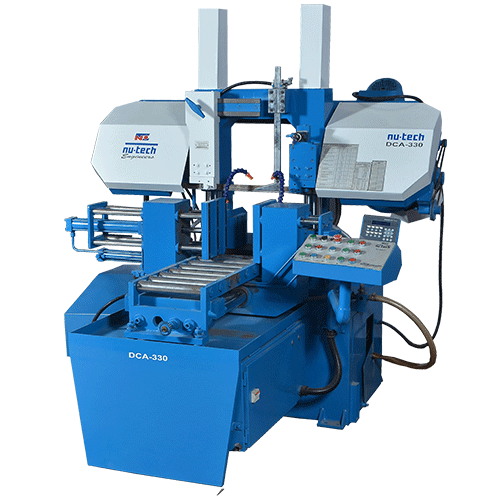

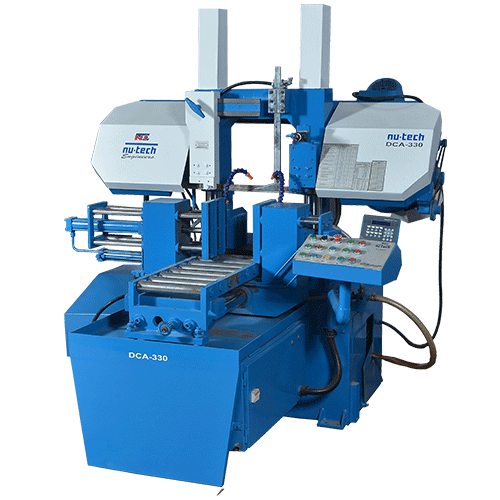

Automatic Bandsaw Machines: Maximum Productivity

At the pinnacle of efficiency and innovation, NU-TECH’s automatic bandsaw machines offer the highest level of automation. Designed for continuous use, these machines excel in environments where large-scale production runs are common. With features like programmable cutting cycles and automatic feed control, they minimize the need for operator intervention. This not only speeds up production but also enhances the consistency of cuts across large volumes of material.

|

|

|

Choosing the Right Bandsaw Machine

Selecting the right bandsaw machine depends on several factors including the type of material, the desired cut precision, and the volume of production. NU-TECH Engineers provides a consultation service to help businesses choose the most suitable model. By assessing your needs, they can recommend a machine that not only fits your current requirements but also accommodates future growth.

Safety and Maintenance: Ensuring Long-term Performance

Safety is paramount when operating any industrial machinery. NU-TECH’s bandsaw machines come equipped with essential safety features to protect operators from injury. Regular maintenance is also crucial to keep these machines performing at their best. Simple routines such as checking blade sharpness, ensuring all parts are lubricated, and keeping the machine clean can extend its lifespan significantly.

Innovations in Bandsaw Technology

NU-TECH Engineers continually invest in research and development to keep their products at the forefront of technology. Innovations such as improved blade materials for faster and smoother cuts, and enhanced control systems for more precise operations, keep NU-TECH at the industry’s cutting edge. Staying updated with these advancements can provide your business with a competitive advantage.

Sustainable Practices in Manufacturing

In today’s eco-conscious market, sustainability is more important than ever. NU-TECH is committed to sustainable manufacturing practices. This includes using energy-efficient components and recycling materials wherever possible. Choosing a bandsaw machine from NU-TECH not only helps your business stay productive but also environmentally responsible.

Partnering with NU-TECH for Your Cutting Needs

Partnering with NU-TECH Engineers means more than just buying a machine. It means gaining a partner who is invested in your success. Our customer service and after-sales support ensure that you get the most out of your investment. With a range of machines and a commitment to quality, NU-TECH is the go-to manufacturer for bandsaw machines.

In conclusion, whether your business deals with metal, wood, or any other materials, a bandsaw machine from NU-TECH Engineers can enhance your cutting operations. Their range of manual, semi-automatic, and automatic bandsaw machines ensures there is a perfect match for every need. Embrace the efficiency and innovation offered by NU-TECH and see how your production capabilities expand.

For more information, visit our product page to explore our comprehensive range of bandsaw machines. Equip your business with cutting-edge technology and drive your productivity today!

Of course, any request in regards to our thing range and our associations make it a feature us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242