Bandsaw Machine Manufacturer

Bandsaw Machines

May 28, 2024

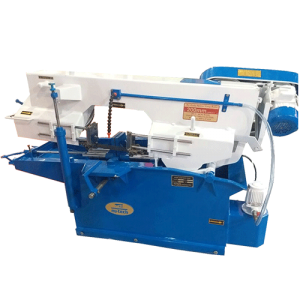

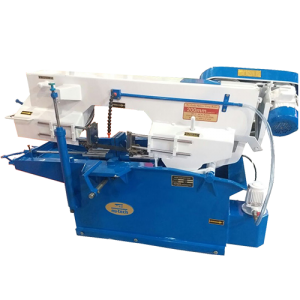

Bandsaw Metal Cutting Machine

June 4, 2024NU-TECH Engineers: The Premier Bandsaw Machine Manufacturer

When choosing the best bandsaw machine manufacturer, NU-TECH Engineers stands out. We offer a wide range of manual, semi-automatic, and automatic bandsaw machines, engineered with precision and durability in mind. Our machines are designed for versatility, reliability, and exceptional performance.

Understanding Bandsaw Machines

Bandsaw machines are essential in cutting operations for industries like metalworking, woodworking, and construction. They provide clean, accurate cuts on various materials with consistent results. At NU-TECH Engineers, we understand the unique requirements of each industry and tailor our machines to fulfil those demands efficiently.

Types of Bandsaw Machines We Offer

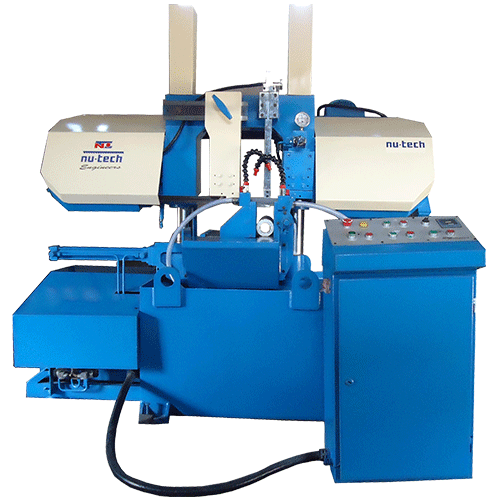

1. Manual Bandsaw Machine

A manual bandsaw machine is worked manually, making it ideal for studios and private ventures. These machines are financially savvy, easy to use, and require insignificant upkeep. They are reasonable for low-volume eliminating positions and guarantee exact cuts on more modest workpieces.

|

|

|

|

|

|

|

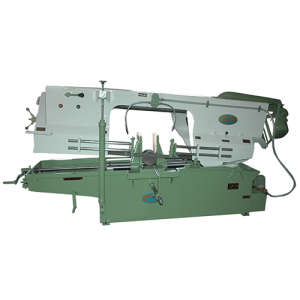

2. Semi-Automatic Bandsaw Machine

Semi-automatic bandsaw machines computerize a few cycles, offering a mix of manual and automatic elements. The machine clips the material, plays out the cut, and returns the saw arm to its underlying position. This computerization further develops efficiency while keeping up with adaptability for medium-volume cutting.

|

|

|

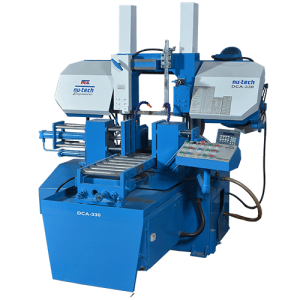

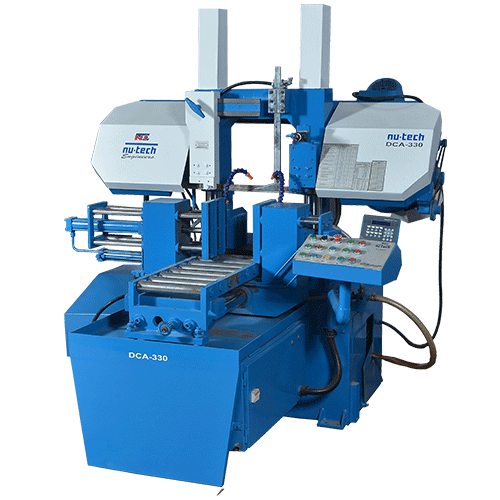

3. Automatic Bandsaw Machine

Automatic bandsaw machines offer total robotization, reasonable for high-volume creation lines. These machines handle the whole cutting interaction, from material taking care of to cutting and resetting. They amplify effectiveness, limit material waste, and guarantee predictable cuts without fail. Their easy-to-use interfaces permit administrators to control the cutting system effortlessly.

|

|

|

Why Choose NU-TECH Engineers for Your Bandsaw Machine Needs?

- Quality Assurance: Each machine is crafted with top-notch materials to ensure long-lasting durability and performance.

- Technical Expertise: Our team combines technical knowledge with industry experience to design and manufacture state-of-the-art bandsaw machines.

- Customization Options: We offer customizable solutions to meet the unique needs of your business.

- After-Sales Support: Our dedicated support team is always ready to assist with installation, maintenance, and troubleshooting.

Optimizing Bandsaw Machine Performance

To make the most of your bandsaw machine, follow these tips:

- Regularly inspect and maintain the blades to extend their lifespan.

- Ensure accurate blade tension to minimize material waste.

- Match the blade type and tooth pattern with the material for consistent cuts.

- Train operators to identify issues promptly and maintain machine efficiency.

Conclusion

NU-TECH Engineers is your trusted partner for high-quality bandsaw machines. Whether you need a manual, semi-automatic, or automatic bandsaw machine, we have the perfect solution for your business. We prioritize quality, efficiency, and customer satisfaction in every product. Reach out today to find the ideal bandsaw machine that meets your specific needs.

any deals concerning our thing range and our affiliations don’t stop quickly contacting us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242