Bandsaw Machine Manufacturer

Bandsaw Machines Manufacturer

August 13, 2024

Bandsaw Machine in Chennai

August 17, 2024Bandsaw Machine Manufacturer

When it comes to precision cutting, choosing the right bandsaw machine is crucial. As a leading bandsaw machine manufacturer, NU-TECH Engineers offers a range of bandsaw machines designed to meet diverse industrial needs. Whether you require manual, semi-automatic, or automatic bandsaws, our machines provide the accuracy and efficiency your business demands.

Understanding Bandsaw Machines

Bandsaw machines are essential in industries requiring precision cutting of metals, wood, and other materials. These machines use a long, sharp blade consisting of a continuous band of toothed metal. The blade is mounted on two wheels, rotating continuously, which allows for precise and consistent cutting. Bandsaws are versatile and can cut through a variety of materials with ease.

Types of Bandsaw Machines

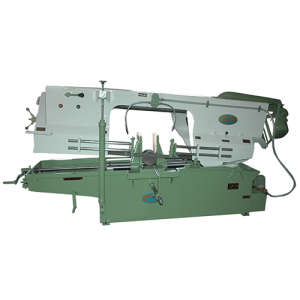

1. Manual Bandsaw Machine

Manual bandsaw machines are perfect for businesses that need control over the cutting process. These machines require an operator to manually feed the material into the blade. The operator has complete control over the cutting speed and pressure, making it ideal for jobs that require detailed work and customization.

|

|

|

|

|

|

|

Key benefits of manual bandsaw machines include:

- Precision: Ideal for intricate cuts where accuracy is paramount.

- Control: Operators have full control over the cutting process.

- Cost-Effective: Lower initial investment compared to automated models.

However, manual bandsaw machines are labour-intensive and may not be suitable for high-volume production.

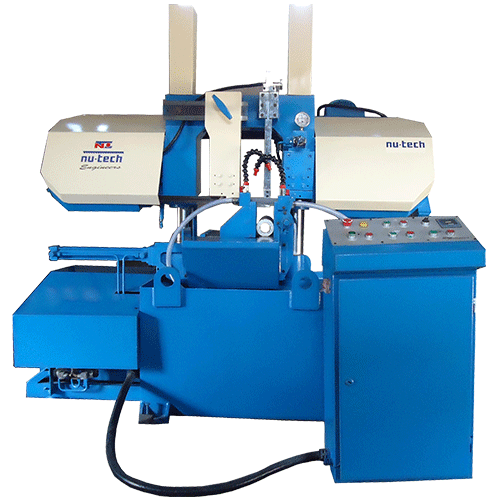

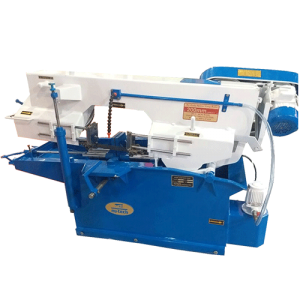

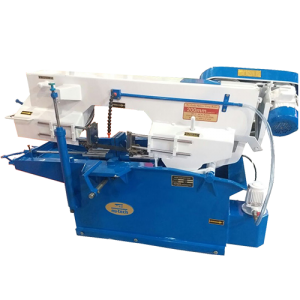

2. Semi-Automatic Bandsaw Machine

Semi-automatic bandsaw machines offer a balance between manual control and automation. In these machines, the material feeding process is automated, but the operator controls the blade’s operation. This combination allows for increased productivity while maintaining a degree of manual control over the cutting process.

|

|

|

Key benefits of semi-automatic bandsaw machines include:

- Efficiency: Faster cutting process compared to manual machines.

- Flexibility: Allows for operator intervention when needed.

- Consistency: Delivers more consistent results with less manual effort.

These machines are suitable for businesses that need to increase productivity without fully automating the cutting process.

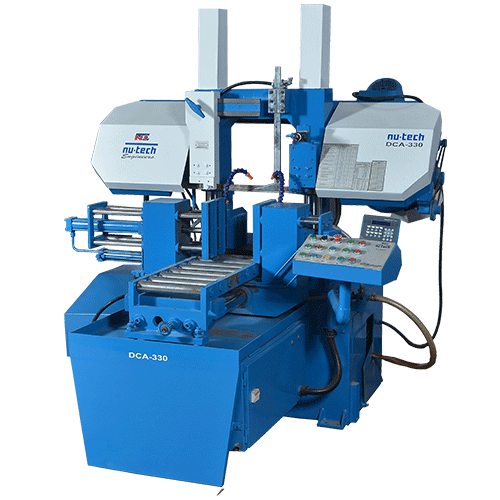

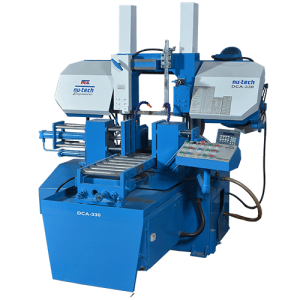

3. Automatic Bandsaw Machine

Automatic bandsaw machines are designed for high-volume production environments. In these machines, both the material feeding and cutting processes are fully automated. The operator’s role is limited to setting up the machine and monitoring its operation. This level of automation significantly reduces labour costs and increases productivity.

|

|

|

Key benefits of automatic bandsaw machines include:

- High Productivity: Ideal for large-scale production with minimal manual intervention.

- Precision: Consistent, high-quality cuts every time.

- Time-Saving: Faster cutting process, reducing overall production time.

While automatic bandsaw machines require a higher initial investment, the return on investment is quickly realized through increased efficiency and reduced labour costs.

Why Choose NU-TECH Engineers?

At NU-TECH Engineers, we pride ourselves on manufacturing top-quality bandsaw machines that meet the highest industry standards. Our machines are built to last, ensuring durability and reliability in demanding industrial environments. We understand that every business has unique needs, which is why we offer a range of bandsaw machines to suit different applications.

Our commitment to innovation and quality has made us a trusted name in the industry. We use the latest technology and manufacturing techniques to ensure our machines deliver superior performance and precision. Whether you are in metalworking, woodworking, or any other industry requiring precise cutting, NU-TECH Engineers has the right solution for you.

Conclusion

Bandsaw machines are vital tools in many industries, and choosing the right type can greatly impact your productivity and quality of work. Whether you need a manual, semi-automatic, or automatic bandsaw machine, NU-TECH Engineers has the expertise and range of products to meet your needs. Our commitment to quality ensures that our machines deliver the precision, durability, and efficiency required in today’s competitive market.

Of course, any request in regards to our thing range and our associations make it a feature us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242