Bandsaw Machines

Bandsaw Machine in Coimbatore

January 18, 2024

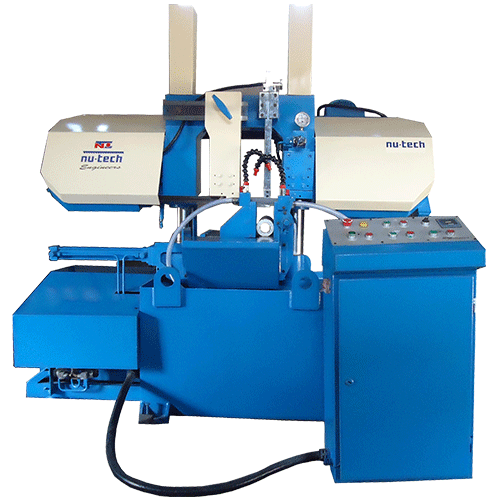

Bandsaw Machine Manufacturer

January 23, 2024In the realm of woodworking and metalworking, bandsaw machines stand tall as versatile tools that revolutionize cutting precision and efficiency. Whether you’re a seasoned craftsman or a DIY enthusiast, understanding the ins and outs of bandsaw machines is essential for achieving impeccable results in your projects.

A Bandsaw machine is indispensable in various industries, offering a dynamic approach to cutting materials. Unlike traditional saws, bandsaws utilize a continuous band of toothed metal to make precise cuts. This unique design ensures smoother and more accurate cuts, making it a must-have for professionals seeking perfection.

Types of Bandsaw Machines: Meeting Every Cutting Need

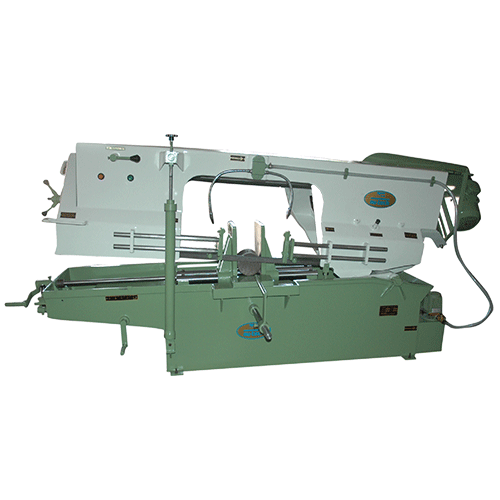

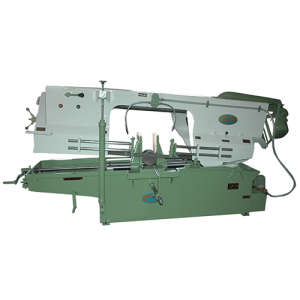

Manual Bandsaw Machine

|

|

|

|

|

|

|

- Ideal for Beginners: These machines require manual control, making them suitable for hobbyists and small workshops.

- Customizable Cuts: Operators can adjust the blade manually for unique cuts, offering creative freedom.

- Cost-Effective: Generally less expensive, they are a great starting point for those on a budget.

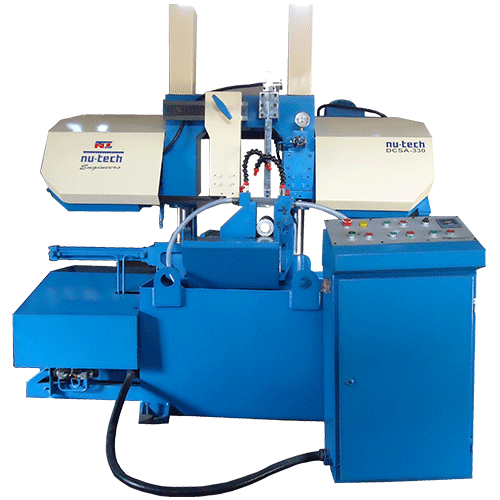

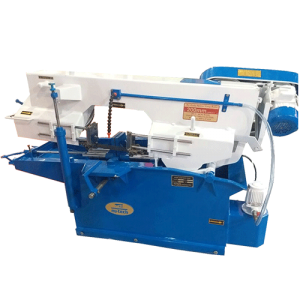

Semi-Automatic Bandsaw Machine

|

|

|

- Enhanced Productivity: Semi-automatic machines blend manual and automated features, increasing cutting speed and consistency.

- User-Friendly: They reduce the operator’s workload while maintaining control over the cutting process.

- Versatile Applications: Ideal for medium-sized workshops and varied cutting tasks.

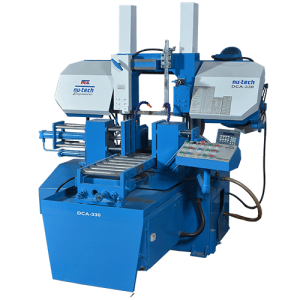

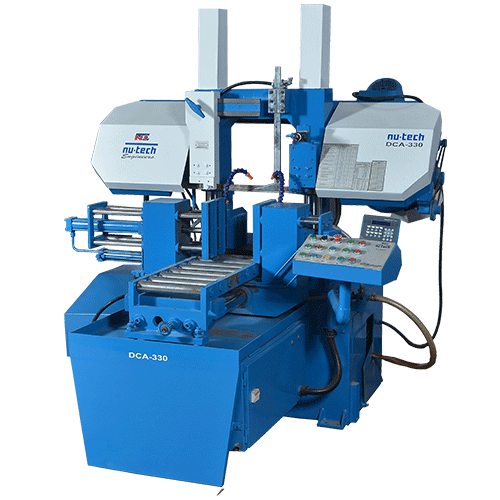

Automatic Bandsaw Machine

|

|

|

- High Efficiency: Fully automated, these machines are designed for high-volume, repetitive tasks.

- Precision and Consistency: They ensure uniform cuts, crucial in large-scale production.

- Time-Saving: With programmable settings, automatic machines save significant time and labour.

Benefits:

- Enhanced Precision: Bandsaw machines deliver precise cuts, making them ideal for intricate designs and detailed work. This accuracy translates to higher-quality finished products.

- Time Efficiency: With adjustable cutting speeds and rapid material feed capabilities, bandsaw machines significantly reduce cutting time. This efficiency boosts overall productivity in your workshop.

- Versatility in Materials: Whether cutting metal, wood, or other materials, bandsaw machines offer unparalleled versatility. This adaptability makes them a valuable asset in various industries.

- Cost-Effective Operations: The precision and efficiency of bandsaw machines contribute to cost savings. Reduced material wastage and faster cutting processes result in a more economical production line.

Optimal Usage Scenarios

- Metal Fabrication: Bandsaw machines are widely used in metal fabrication for cutting various metals, including steel and aluminium. Their ability to handle intricate cuts makes them indispensable in creating metal components for diverse applications.

- Woodworking: In woodworking, bandsaw machines shine in crafting intricate designs, curved cuts, and veneer slicing. Woodworkers appreciate the precision and versatility these machines bring to their projects.

- Renovation and Construction: Bandsaw machines play a crucial role in renovation and construction projects. Their adaptability contributes to efficient construction processes from cutting pipes to shaping structural elements.

- Automotive Industry: Precision cuts are paramount in the automotive industry. Bandsaw machines are employed for cutting metal components used in vehicle manufacturing, ensuring quality and accuracy.

Elevate Your Cutting Experience with Bandsaw Machine

Investing in a bandsaw machine is a strategic move for businesses aiming to enhance their cutting capabilities. From features that prioritize precision to myriad benefits and versatile usage scenarios, bandsaw machines stand as pillars of efficiency in various industries.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242