Bandsaw Machines

Bandsaw Machine in Coimbatore

February 24, 2024

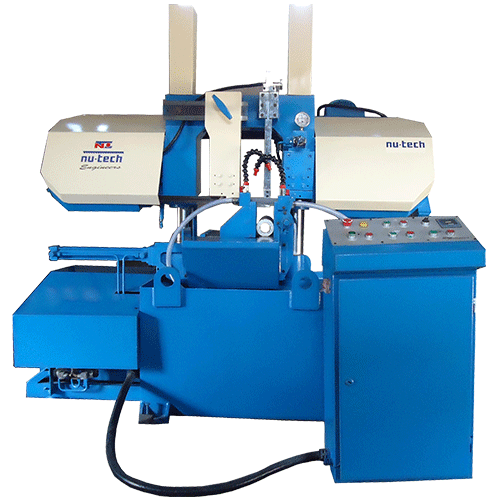

Bandsaw Machine Manufacturer

March 5, 2024In today’s fast-paced industrial landscape, Bandsaw Machines have become indispensable for precision cutting and shaping across various materials. Whether you’re a seasoned professional or a newcomer to the world of machining, understanding the needs, features, benefits, and applications of Bandsaw Machines is key to unlocking their full potential.

Bandsaw Machines: Meeting Diverse Industrial Needs

Bandsaw machines cater to a wide array of industrial needs, ranging from metalworking to woodworking. Their versatility makes them an essential tool for businesses involved in fabrication, construction, and manufacturing. Let’s delve into the core aspects that make bandsaw machines an integral part of any cutting-edge operation.

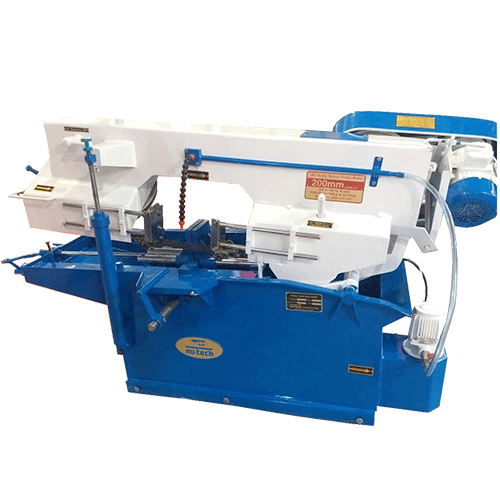

Manual Bandsaw Machine

|

|

|

|

|

|

|

- Ideal for Beginners: These machines require manual control, making them suitable for hobbyists and small workshops.

- Customizable Cuts: Operators can adjust the blade manually for unique cuts, offering creative freedom.

- Cost-Effective: Generally less expensive, they are a great starting point for those on a budget.

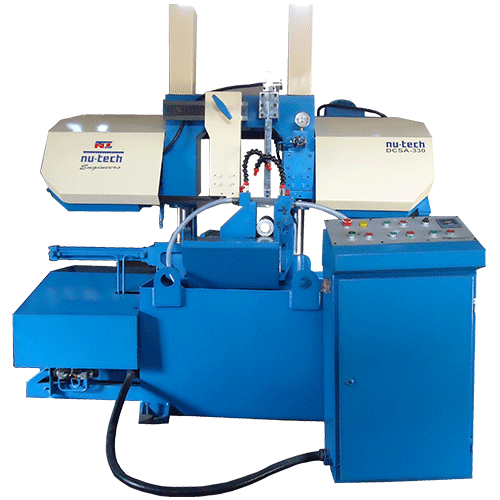

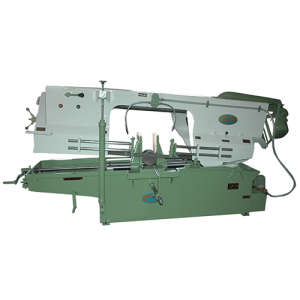

Semi-Automatic Bandsaw Machine

|

|

|

- Enhanced Productivity: Semi-automatic machines blend manual and automated features, increasing cutting speed and consistency.

- User-Friendly: They reduce the operator’s workload while maintaining control over the cutting process.

- Versatile Applications: Ideal for medium-sized workshops and varied cutting tasks.

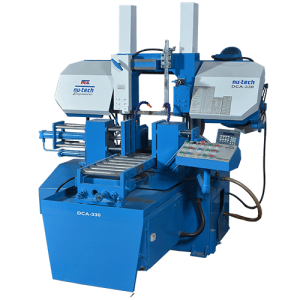

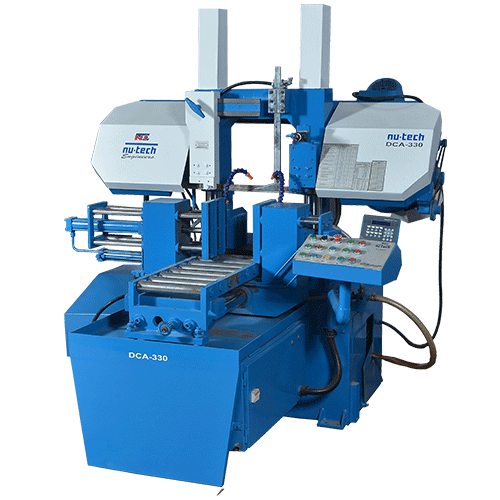

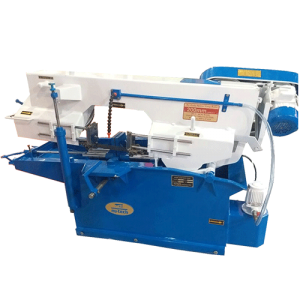

Automatic Bandsaw Machine

|

|

|

- High Efficiency: Fully automated, these machines are designed for high-volume, repetitive tasks.

- Precision and Consistency: They ensure uniform cuts, crucial in large-scale production.

- Time-Saving: With programmable settings, automatic machines save significant time and labour.

Unveiling the Features: Precision in Every Cut

- Cutting Capacity: Bandsaw machines boast impressive cutting capacities, allowing them to handle large workpieces with ease. Whether you’re dealing with metal, wood, or other materials, these machines ensure accuracy and consistency in every cut.

- Adjustable Speeds: The ability to adjust cutting speeds provides flexibility in handling different materials. Bandsaw machines allow operators to tailor the speed according to the material’s hardness, ensuring optimal performance and prolonging blade life.

- Blade Varieties: From fine cuts to aggressive resawing, bandsaws accommodate various blade types. This versatility empowers users to tackle a diverse range of cutting tasks without compromising on precision.

- Durable Construction: Built to withstand the rigours of industrial use, bandsaw machines are often constructed with robust materials. This durability ensures a long lifespan, making them a cost-effective investment for businesses.

Unlocking the Benefits: Efficiency and Precision Unleashed

- Time Efficiency: Bandsaw machines streamline the cutting process, reducing manual labour and saving valuable time. Their efficiency is particularly evident in repetitive cutting tasks, where precision and speed go hand in hand.

- Cost Savings: The precision offered by bandsaw machines minimizes material wastage, translating into cost savings for businesses. Additionally, their durability and low maintenance requirements contribute to long-term financial benefits.

- Enhanced Safety: Equipped with advanced safety features, bandsaws prioritize operator well-being. From blade guards to emergency stop mechanisms, these machines are designed with user safety in mind, fostering a secure working environment.

- Versatility in Applications: Bandsaw machines find applications across a spectrum of industries. From intricate woodworking projects to heavy-duty metal cutting, their adaptability makes them indispensable in diverse manufacturing and fabrication processes.

Empowering Industries: Applications Across the Spectrum

- Woodworking: In woodworking, bandsaw excels at intricate cuts, curved designs, and resawing large timber. Woodworkers appreciate the finesse and accuracy offered by these machines, making them a staple in furniture manufacturing and crafting.

- Metalworking: For metalworking, bandsaw machines provide the precision required for cutting various metals. Whether it’s shaping metal sheets, pipes, or solid bars, these machines deliver consistent results, making them indispensable in metal fabrication workshops.

- Construction: In construction, bandsaw machines play a crucial role in cutting materials like concrete, steel, and other construction-grade materials. Their efficiency and accuracy contribute to the seamless execution of construction projects.

- Manufacturing: In manufacturing, bandsaws contribute to the production of components with precise dimensions. From automotive parts to industrial machinery components, these machines ensure consistency and quality in mass production settings.

Elevate Your Precision: Invest in Bandsaw Machines Today!

Discover the unmatched capabilities of bandsaw machines – from their cutting-edge features to the array of benefits they offer across various applications. Embrace precision, efficiency, and versatility in your industrial processes by integrating bandsaw machines into your toolkit.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242