Bandsaw Machines

Bandsaw Machine Manufacturer

March 5, 2024

Bandsaw Machine Manufacturer

March 9, 2024Unlock Efficiency: Discover Bandsaw Machine Advantages

In today’s fast-paced industrial environment, achieving efficiency and precision in cutting operations is paramount. Bandsaw machines, with their versatile functionality, stand out as essential tools in various sectors, including woodworking, metalworking, and material fabrication. Bandsaw machines are specialized saws consisting of a continuous band of toothed metal stretched between two or more wheels. Their unique design enables users to perform precise cuts, including irregular or curved shapes, something not easily achievable with traditional saws. Let’s explore the reasons behind the growing reliance on bandsaw machines.

Why Do We Need Bandsaw Machines?

The need for bandsaw machines arises from their unmatched flexibility and precision. Whether it’s creating intricate designs in woodworking projects or ensuring accurate cuts in metal fabrication, bandsaw machines provide a solution that other cutting tools cannot match. Additionally, their ability to handle a variety of materials with minimal wastage makes them a cost-effective option for many.

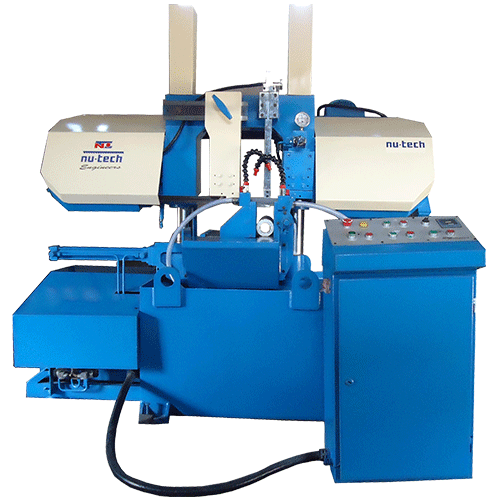

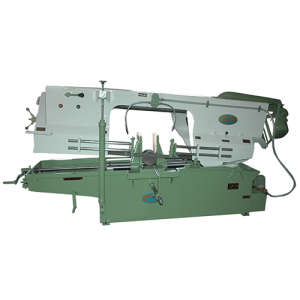

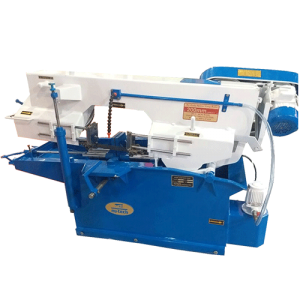

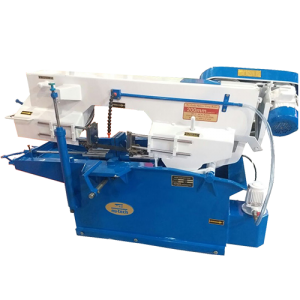

Manual Bandsaw Machine

|

|

|

|

|

|

|

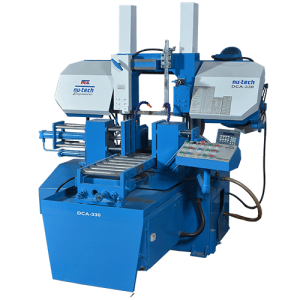

Semi-Automatic Bandsaw Machine

|

|

|

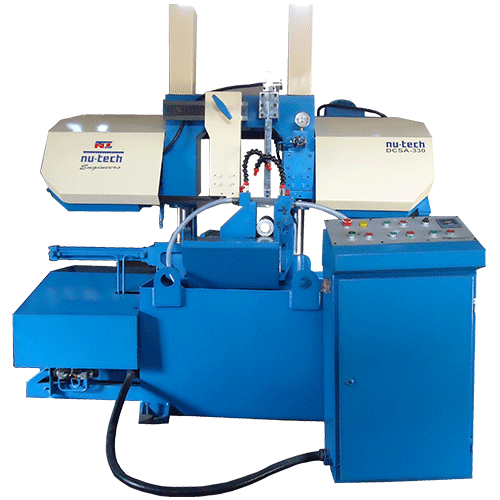

Automatic Bandsaw Machine

|

|

|

Key Features of Bandsaw Machines

- Variable Speed Settings: Allows the user to adjust the speed based on the material being cut, enhancing cut quality and extending blade life.

- Adjustable Blade Guides: Improve blade stability and precision by adjusting to various thicknesses and types of materials.

- Tilted Table: Enables angled cuts, offering versatility in projects that require complex shapes and designs.

- Dust Collection Ports: Keeps the work area clean and reduces health risks associated with airborne particles.

Benefits

- Versatility: Can cut a wide range of materials, from wood and metal to plastics and composites.

- Precision: Delivers accurate cuts, including complex curves and angles, with a high-quality finish.

- Efficiency: Saves time and material by making precise cuts the first time, reducing the need for secondary operations.

- Safety: Generally safer than other saws due to the blade’s downward action and features like blade guards.

Usages

Bandsaw machines find applications in various industries, highlighting their adaptability:

- Woodworking: Crafting furniture, creating intricate designs, and resizing lumber.

- Metalworking: Cutting through metal stock, including steel, aluminium, and copper, for fabrication and repair work.

- Plastics and Composites: Precision cutting of plastics and composite materials for manufacturing parts and prototypes.

Maximizing the Potential of Your Bandsaw Machine

To fully benefit from a bandsaw machine, regular maintenance, including blade tensioning, cleaning, and lubrication, is crucial. Additionally, selecting the right blade for the material and cut type can significantly impact the quality of the output and the longevity of the machine.

Conclusion

Bandsaw machines are unparalleled in their ability to meet diverse cutting needs with precision and efficiency. By understanding their features, benefits, and usages, users can significantly enhance their cutting operations, whether in a professional setting or a personal workshop. As technology advances, the evolution of bandsaw machines will continue to offer even greater capabilities, solidifying their status as indispensable tools in the cutting industry.

Embrace the power and versatility of bandsaw machines to elevate your cutting projects to new levels of efficiency and precision.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242