Bandsaw Machines Manufacturer

Bandsaw Machines

August 8, 2024

Bandsaw Machine Manufacturer

August 15, 2024Bandsaw Machines Manufacturer

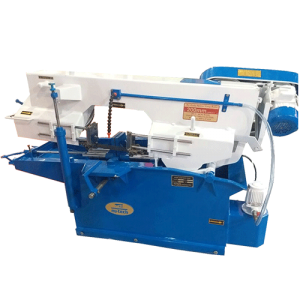

Bandsaw machines are indispensable in the metal and woodworking industries. These machines offer precision cutting, ensuring clean and accurate results. At NU-TECH Engineers, we manufacture bandsaw machines tailored to meet various industrial needs.

Why Choose Bandsaw Machines?

Bandsaw machines are known for their flexibility. They can cut through a great many materials, including metals, wood, and plastics. This makes them an important expansion to any studio or modern setting. Our bandsaw machines at NU-TECH Engineers are intended for strength and execution.

Types of Bandsaw Machines

NU-TECH Engineers offers three main types of bandsaw machines:

- Manual Bandsaw Machine

- Semi-Automatic Bandsaw Machine

- Automatic Bandsaw Machine

Each type caters to different levels of operational needs and budgets. Let’s explore these in detail.

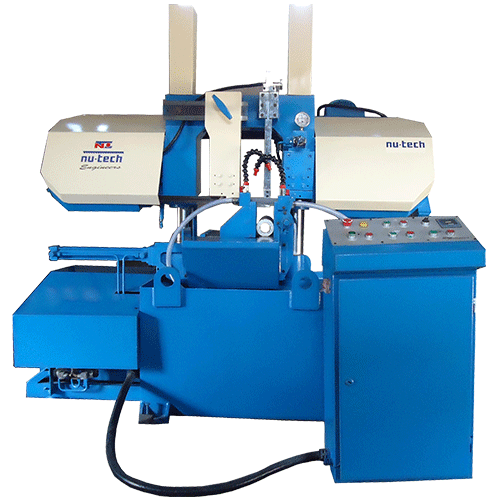

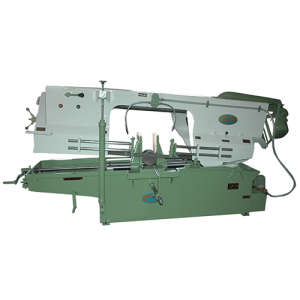

Manual Bandsaw Machine

Manual bandsaw machines are perfect for smaller workshops. These machines require a chairman to manage the material manually. They are great for projects that need an elaborate philosophy. The manual movement considers the specific control over the cutting framework.

|

|

|

|

|

|

|

Key features of our manual bandsaw machines include:

- Robust construction

- Easy operation

- Cost-effective solution

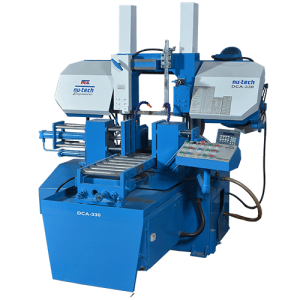

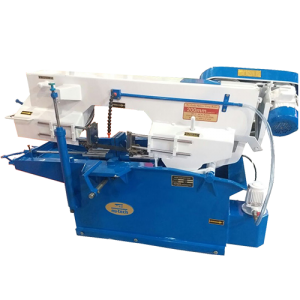

Semi-Automatic Bandsaw Machine

Semi-automatic bandsaw machines offer harmony among manual and automated functions. These machines robotize a piece of the cutting system, lessening administrator weariness. The administrator needs to stack and empty the material, yet the cutting system is automated.

|

|

|

Benefits of semi-automatic bandsaw machines:

- Increased productivity

- Reduced operator effort

- Consistent cutting accuracy

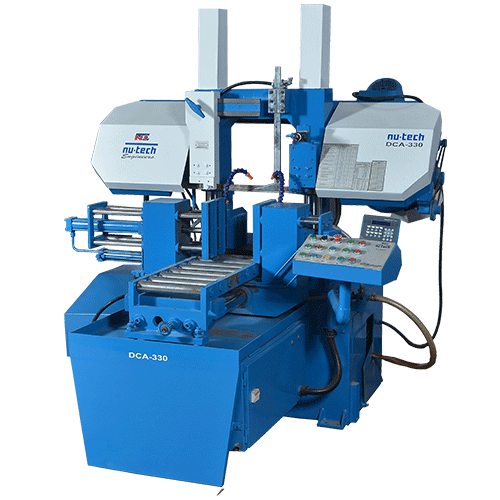

Automatic Bandsaw Machine

Automatic bandsaw machines are designed for high-volume production. These machines require minimal operator intervention. They are ideal for large industrial applications where efficiency and precision are crucial.

|

|

|

Advantages of automatic bandsaw machines:

- High-speed cutting

- Minimal operator intervention

- Suitable for large-scale production

Why NU-TECH Engineers?

NU-TECH Engineers is focused on giving excellent bandsaw machines. Our machines are worked with accuracy designing and the most recent technology. We guarantee each machine satisfies industry guidelines and conveys extraordinary execution.

Quality and Durability

We utilize high-grade materials to manufacture our bandsaw machines. This guarantees they are strong and can endure thorough use. Our machines go through severe quality checks to ensure dependability.

Customer Support

At NU-TECH Engineers, customer satisfaction is a priority. We offer comprehensive support to help you choose the right bandsaw machine. Our team is available to answer any questions and provide technical assistance.

Innovation and Technology

We continually advance to further develop our bandsaw machines. Our innovative work group chips away at coordinating the most recent innovation. This guarantees our machines are efficient, reliable, and in front of the opposition.

Applications of Bandsaw Machines

Bandsaw machines are used in various industries, including:

- Metalworking

- Woodworking

- Plastics manufacturing

- Construction

Their ability to cut precise shapes and sizes makes them versatile and essential for many applications.

Maintenance Tips for Bandsaw Machines

Regular maintenance is crucial for the longevity of bandsaw machines. Here are some tips:

- Keep the blades sharp

- Lubricate moving parts regularly

- Inspect the machine for wear and tear

- Follow the manufacturer’s maintenance guidelines

Conclusion

Bandsaw machines from NU-TECH Engineers give accuracy, effectiveness, and strength. Whether you want a manual, semi-automatic, or automatic bandsaw machine, we have the right answer for you. Investigate our scope of bandsaw machines and upgrade your workshop’s abilities.

Of course, any request in regards to our thing range and our associations make it a feature us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242