Bandsaw Metal Cutting Machine

Bandsaw Machine Manufacturer

June 1, 2024

Bandsaw Machines in Chennai

June 6, 2024In the metalworking industry, precision and efficiency are paramount. Bandsaw metal cutting machines offer a versatile and powerful solution for cutting a wide range of materials. NU-TECH Engineers, a leading manufacturer, provides three distinct bandsaw machine types to cater to your specific needs: manual, semi-automatic, and automatic. This guide explores the functionalities and advantages of each type, empowering you to make an informed decision for your workshop.

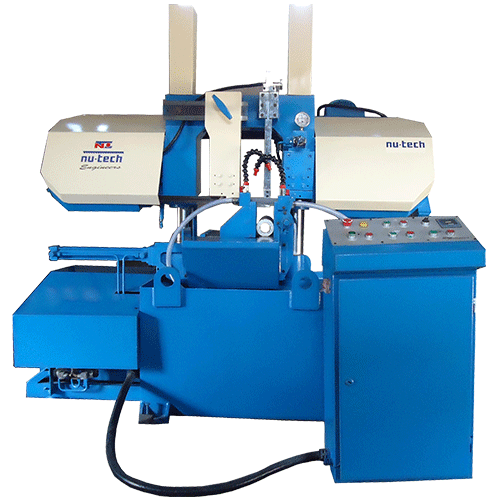

Manual Bandsaw Machines: Hands-on Control for Precise Cuts

|

|

|

|

|

|

|

Manual bandsaw machines are ideal for workshops requiring a cost-effective and user-friendly metal-cutting solution. These machines offer:

- Simple operation: Manual control over blade feed and cutting speed allows for precise cuts on various materials, from thin sheets to solid bars.

- Versatility: They can handle straight cuts, mitre cuts, and even contour cutting with the right blade selection.

- Compact size: Their smaller footprint makes them perfect for workshops with limited space.

Suited for:

- Prototyping and small-scale production runs.

- DIY enthusiasts and hobbyists.

- Workshops requiring occasional or light-duty metal cutting.

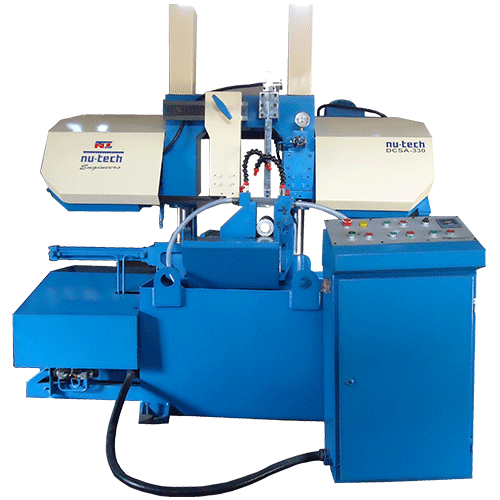

Semi-Automatic Bandsaw Machines: Enhanced Efficiency for Repetitive Tasks

|

|

|

Semi-automatic bandsaws bridge the gap between manual and fully automated machines. They offer several advantages:

- Automated blade feed: This feature ensures consistent pressure and cutting depth, reducing operator fatigue and improving cut quality.

- Increased cutting speed: Faster cutting cycles lead to higher production output.

- Maintains manual control: Operators can still adjust cutting parameters for intricate cuts.

Suited for:

- Workshops with moderate metal cutting demands.

- Production runs involving repetitive cuts of similar materials.

- Applications where a balance between precision and efficiency is required.

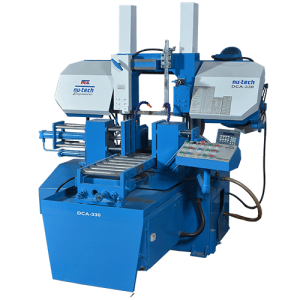

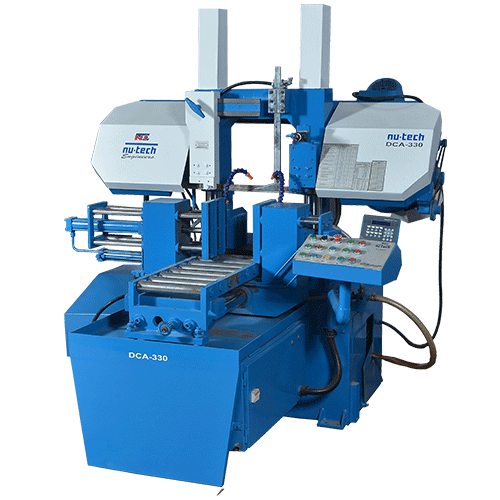

Automatic Bandsaw Machines: Automated Powerhouse for High-Volume Cutting

|

|

|

Automatic bandsaw machines are the workhorses of industrial metalworking settings. They provide the highest level of automation and efficiency:

- Full automation: These machines handle the entire cutting process, including material feeding, cutting, and blade stopping, minimizing operator involvement.

- Advanced features: Automatic features like programmable cutting parameters and automatic shut-off enhance safety and production consistency.

- High cutting capacity: Designed for heavy-duty applications and bulk material processing.

Suited for:

- High-volume metal fabrication shops.

- Mass production environments demand consistent and rapid cutting.

- Applications requiring minimal operator intervention.

NU-TECH Engineers: Your Trusted Partner in Metalworking Solutions

NU-TECH Engineers stands out as a reliable provider of high-quality bandsaw metal cutting machines. Their commitment to innovation ensures you receive machines built for durability, precision, and efficiency.

Get a Quote Today!

Contact us today to discuss your specific metalworking needs and receive a personalized quote for the most suitable bandsaw machine for your workshop. We are dedicated to helping you achieve optimal metal-cutting performance.

Then again, any inquiry regarding our thing range and our organizations make it a highlight us…

Our contact details are

(M) 098257 77803

(M) 098798 34509

(F) 02752 240242